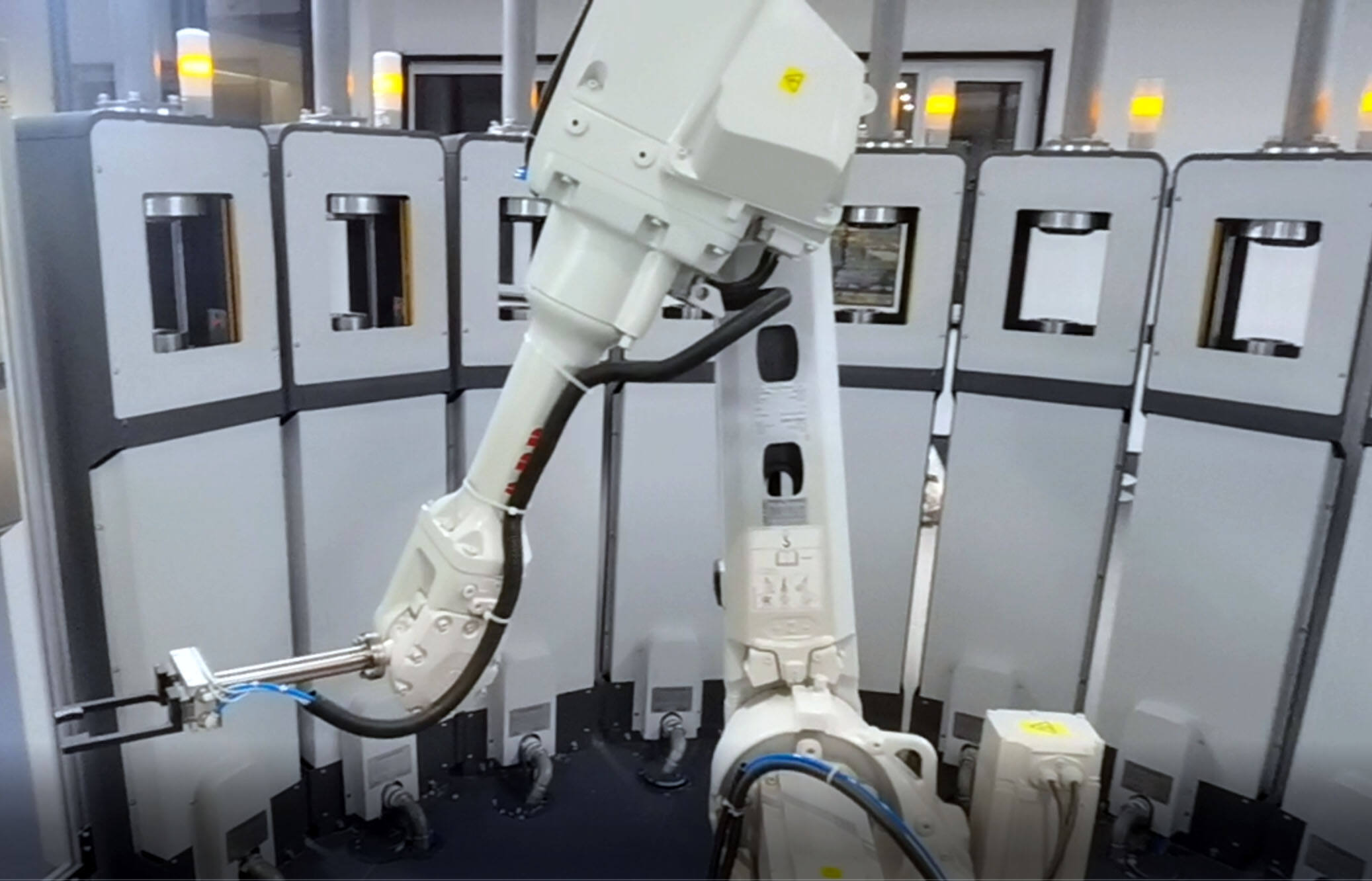

pneumatic pipe system

The pneumatic pipe system represents a revolutionary approach to material transport and handling, utilizing compressed air to move various materials through a network of pipes. This sophisticated system comprises multiple components including compressors, pipelines, diverter valves, and collection units, all working in harmony to ensure efficient material movement. The system operates by creating pressure differentials that propel materials through sealed pipes, enabling quick and secure transport across various distances and elevations. In industrial settings, these systems excel at handling diverse materials, from fine powders and granules to larger solid items, making them invaluable in manufacturing, pharmaceutical, and food processing industries. The technology incorporates advanced monitoring systems and automated controls, ensuring precise material flow management and reducing the need for manual intervention. One of its most notable features is the ability to transport materials in any direction, whether horizontally, vertically, or around corners, without mechanical handling or conveyor systems. The sealed nature of pneumatic pipe systems also provides exceptional protection against contamination and material loss, while simultaneously maintaining a clean working environment. These systems can be customized to meet specific industry requirements, with options for different pipe materials, sizes, and configurations to accommodate various operational needs.