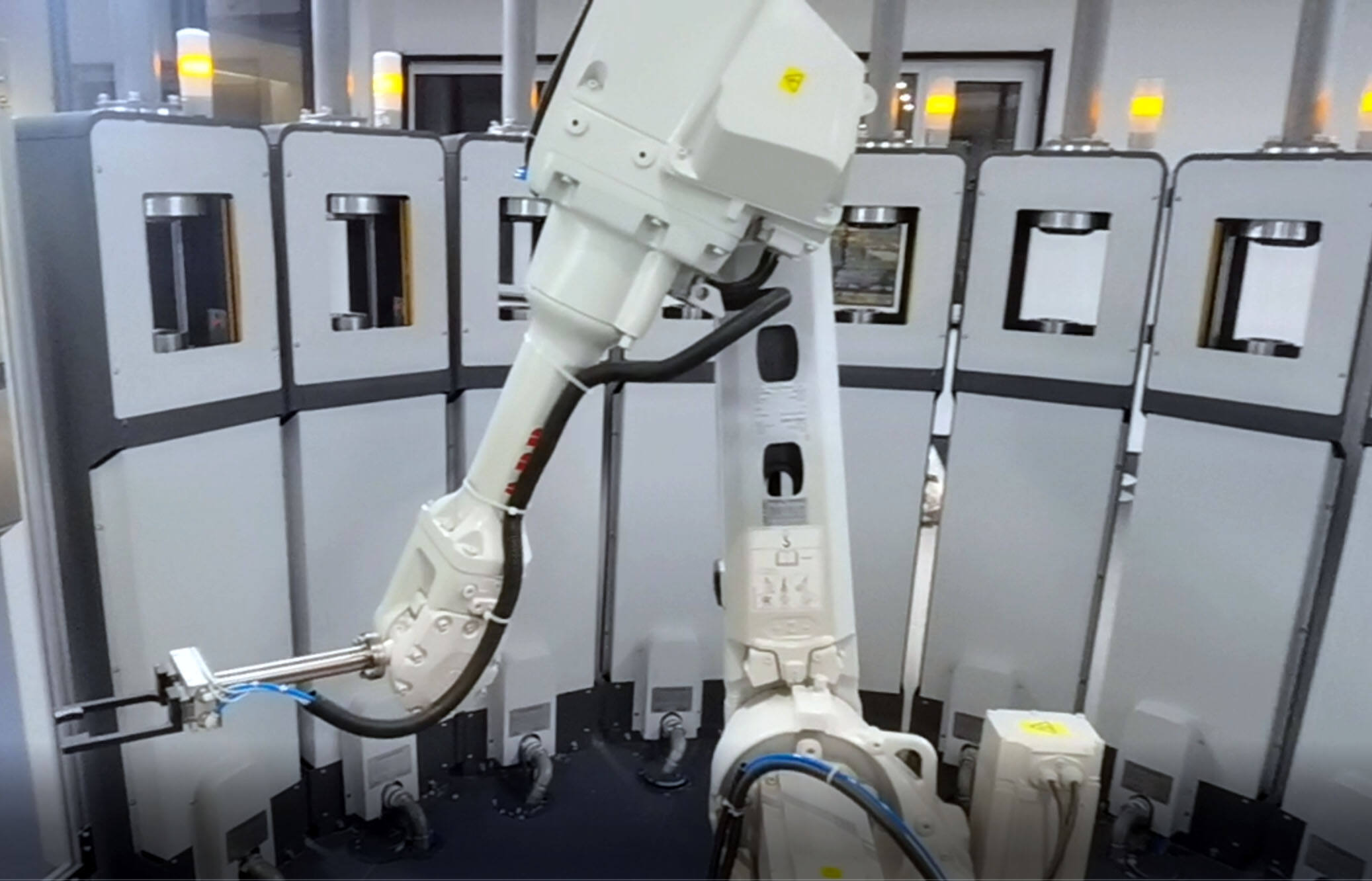

automated pneumatic tube transport

Automated pneumatic tube transport represents a cutting-edge solution for efficient material movement across various facilities. This system utilizes compressed air to propel carriers through a network of tubes, enabling rapid and secure transportation of items between different locations. The technology incorporates advanced control systems, tracking capabilities, and automated routing mechanisms to ensure precise delivery and real-time monitoring. Modern pneumatic tube systems feature sophisticated carriers designed to protect contents during transit, with specialized compartments for different types of materials. The system's infrastructure includes strategically placed stations, transfer units, and blowers that maintain optimal air pressure for smooth operation. Smart integration capabilities allow these systems to connect with existing facility management software, enabling seamless workflow coordination. Applications span across healthcare facilities for transporting medical samples and pharmaceuticals, financial institutions for secure cash movement, industrial facilities for document delivery, and retail environments for efficient cash handling. The technology employs safety mechanisms such as carrier detection systems, automatic fault diagnosis, and backup power supplies to ensure reliable operation. With customizable configurations and scalable designs, these systems can be tailored to meet specific facility requirements while maintaining operational efficiency.