pneumatic pipe price

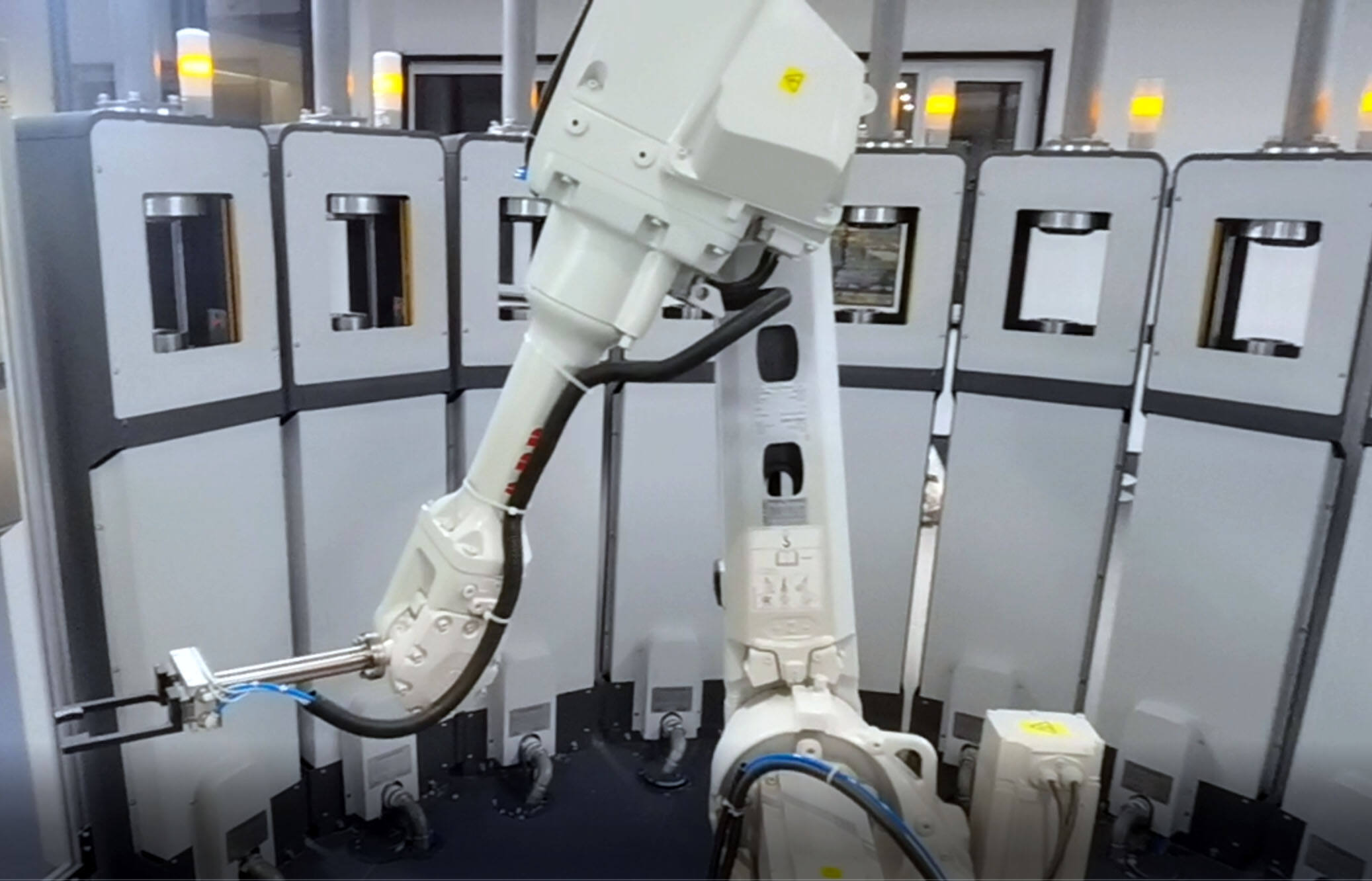

Pneumatic pipe pricing represents a crucial aspect of industrial and commercial applications, encompassing various factors that influence cost effectiveness and system performance. These essential components, designed for compressed air transportation, come in different materials including stainless steel, aluminum, and specialized polymers, each affecting the final price point. The cost structure typically reflects diameter specifications, material quality, pressure ratings, and manufacturing standards. Modern pneumatic pipes feature advanced coatings and treatments that enhance durability and corrosion resistance, directly impacting their market value. The pricing also considers factors such as wall thickness, connection types, and compliance with international safety standards. In industrial settings, these pipes handle pressures ranging from 100 to 200 PSI, requiring precise engineering and quality materials that influence the overall cost. The market offers various price points depending on application requirements, from basic air tool operations to sophisticated automated manufacturing systems. Contemporary pneumatic pipe solutions incorporate innovative designs that minimize air leakage and optimize flow efficiency, features that often justify premium pricing. Understanding pneumatic pipe pricing helps businesses make informed decisions about their compressed air systems, balancing initial investment against long-term operational benefits.