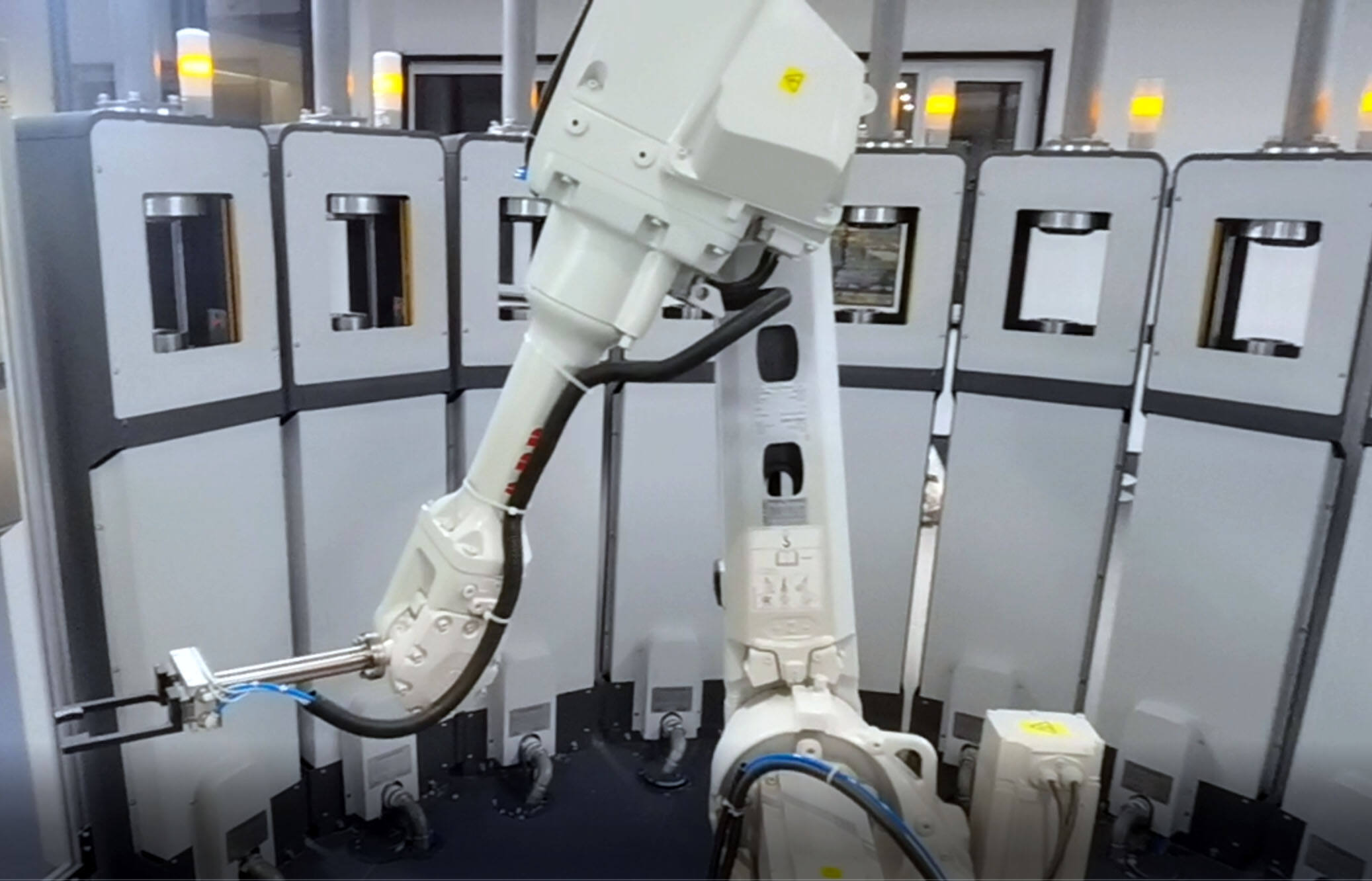

система доставки по трубопроводу

Система доставки труб представляет собой революционный подход к автоматизированной транспортировке материалов, объединяя передовые пневматические технологии с интеллектуальными системами управления. Эта сложная сеть состоит из взаимосвязанных трубок, которые используют сжатый воздух для перемещения контейнеров с различными предметами по заданному пути. Система работает благодаря сложному, но эффективному механизму, в котором вакуум и перепады давления работают одновременно для перемещения контейнеров с контролируемой скоростью, обеспечивая безопасную и надежную доставку содержимого. Технология включает в себя передовые алгоритмы маршрутизации, которые оптимизируют пути доставки и минимизируют время транзита, а также умные датчики, которые отслеживают параметры работы системы и местоположение контейнеров в режиме реального времени. Эти системы находят широкое применение в различных отраслях, включая медицинские учреждения для транспортировки медицинских образцов и материалов, финансовые организации для безопасной доставки документов, промышленные предприятия для распределения компонентов и розничную торговлю для управления денежными средствами. Инфраструктура разработана с функциями резервирования и механизмами безопасности, чтобы обеспечить непрерывную работу, а модульная конструкция системы позволяет легко расширять и настраивать ее в соответствии с конкретными требованиями объекта. Современные системы доставки труб также интегрируются с системами управления зданием и могут управляться через удобные пользовательские интерфейсы, что позволяет эффективно планировать и отслеживать доставку.