Transforming Metal Analysis Through Advanced Automation

The landscape of materials science is experiencing a revolutionary shift as metallurgical testing enters a new era of sophistication and precision. Traditional manual testing methods are rapidly giving way to automated instrument systems, marking a significant evolution in how we analyze and understand metals. This transformation is not merely about replacing human operators – it represents a fundamental change in the accuracy, efficiency, and reliability of metal analysis processes.

Modern metallurgical testing has become the cornerstone of quality control across numerous industries, from aerospace and automotive to construction and electronics. As manufacturing processes become increasingly complex and quality standards more stringent, the role of automated testing systems has become indispensable. These advanced systems are reshaping the future of materials analysis, offering unprecedented levels of precision while significantly reducing the time and resources required for comprehensive testing.

Core Components of Advanced Metallurgical Testing Systems

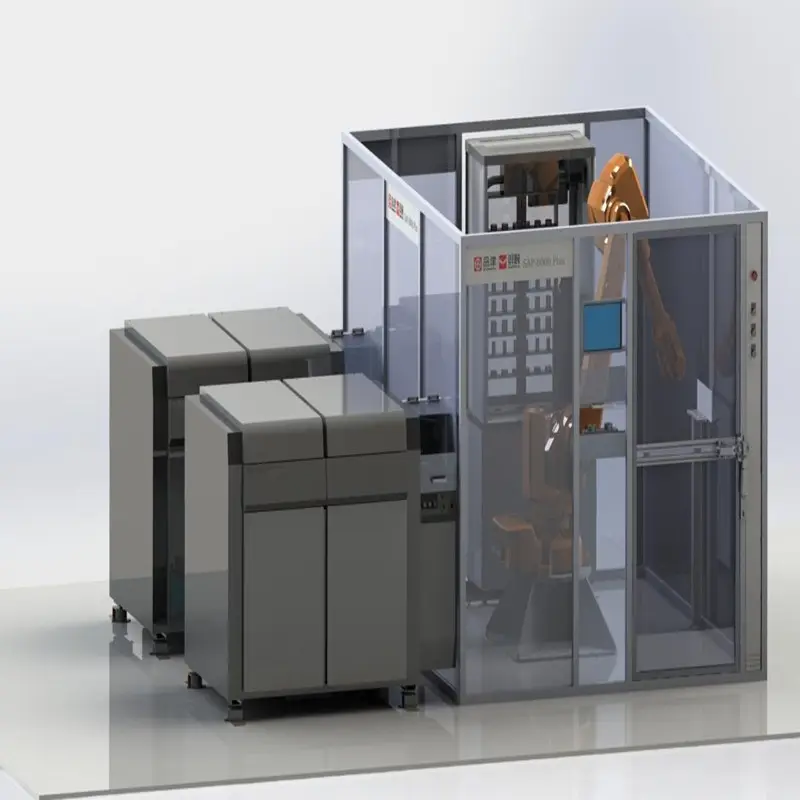

Automated Sample Preparation Units

The foundation of reliable metallurgical testing lies in proper sample preparation. Automated sample preparation systems have revolutionized this critical first step by ensuring consistent specimen quality. These sophisticated units handle everything from cutting and mounting to grinding and polishing, eliminating variables that could compromise test results.

Modern sample preparation systems incorporate intelligent pressure control, automated cleaning cycles, and precise material removal rates. This level of automation not only increases throughput but also ensures that each sample meets exact specifications for testing. The result is a dramatic improvement in the reliability of subsequent analyses and a significant reduction in operator-dependent variations.

Integrated Imaging and Analysis Software

Advanced imaging systems coupled with powerful analysis software form the brain of modern metallurgical testing equipment. These systems can capture high-resolution images of microstructures, perform real-time measurements, and analyze complex material properties with unprecedented accuracy. The software employs sophisticated algorithms to detect and quantify various metallurgical features, from grain size distribution to phase analysis.

Artificial intelligence and machine learning capabilities have further enhanced these systems, enabling them to recognize patterns and anomalies that might be missed by human observers. This technology can process vast amounts of data quickly, providing detailed reports and statistical analyses that help in making informed decisions about material quality and processing parameters.

Enhanced Testing Capabilities and Methodologies

Non-destructive Testing Innovations

The evolution of metallurgical testing has led to remarkable advances in non-destructive testing (NDT) methods. Modern automated systems can perform comprehensive material analysis without compromising the integrity of the test specimen. This capability is particularly valuable in industries where component reliability is critical and destructive testing is not an option.

Advanced NDT techniques now include automated ultrasonic testing, digital radiography, and electromagnetic testing systems. These methods provide detailed information about internal structures, defects, and material properties while maintaining the specimen's usefulness for its intended application. The integration of these technologies with automated handling systems has created highly efficient testing workflows that can process large volumes of samples with minimal human intervention.

Real-time Monitoring and Analysis

Contemporary metallurgical testing systems excel in providing real-time data acquisition and analysis capabilities. This immediate feedback allows for quick adjustments in manufacturing processes and helps maintain optimal quality control standards. The systems can continuously monitor multiple parameters simultaneously, creating comprehensive data sets that offer deeper insights into material behavior and performance.

Real-time monitoring systems are particularly valuable in production environments where rapid decision-making is crucial. They can detect variations in material properties as they occur, enabling immediate corrective actions that prevent the production of substandard materials. This capability significantly reduces waste and improves overall manufacturing efficiency.

Impact on Industry Standards and Quality Control

Standardization and Compliance

Automated metallurgical testing systems have played a pivotal role in establishing and maintaining industry standards. These systems ensure consistent testing procedures across different facilities and geographical locations, making it easier to achieve and verify compliance with international quality standards. The precision and reliability of automated testing have led to more stringent quality requirements, ultimately benefiting end-users across all industries.

The standardization of testing procedures through automation has also simplified the certification process for manufacturers and testing laboratories. Automated systems maintain detailed records of all tests performed, creating an audit trail that demonstrates compliance with required standards and specifications. This documentation is invaluable for quality management systems and regulatory compliance.

Quality Assurance Evolution

The implementation of automated metallurgical testing systems has fundamentally transformed quality assurance processes. These systems provide comprehensive material characterization that goes beyond basic property measurements, offering insights into material performance under various conditions. This detailed analysis helps predict product behavior and longevity, enabling manufacturers to make informed decisions about material selection and processing parameters.

Quality assurance has become more proactive rather than reactive, thanks to the predictive capabilities of automated testing systems. By identifying potential issues before they become problems, manufacturers can optimize their processes and maintain consistent product quality. This approach has led to significant improvements in product reliability and customer satisfaction.

Future Trends and Technological Advancements

Integration with Industry 4.0

The future of metallurgical testing is closely aligned with Industry 4.0 principles. Automated testing systems are increasingly being integrated with smart manufacturing systems, creating seamless connections between quality control and production processes. This integration enables real-time process optimization based on testing results, leading to more efficient and adaptive manufacturing operations.

The incorporation of Internet of Things (IoT) technology allows testing systems to communicate with other manufacturing equipment, creating a connected ecosystem that can respond dynamically to changing conditions. This level of integration represents the next evolution in automated testing, where systems not only perform tests but actively participate in process control and optimization.

Emerging Technologies and Capabilities

The development of new testing technologies continues to expand the capabilities of automated systems. Advanced sensors, improved data analytics, and novel testing methods are being incorporated into next-generation testing equipment. These innovations promise even greater accuracy, faster testing speeds, and more comprehensive material analysis capabilities.

Artificial intelligence and machine learning will play increasingly important roles in metallurgical testing, enabling more sophisticated analysis and prediction of material behavior. These technologies will help identify subtle patterns and correlations in test data that could lead to breakthroughs in material science and manufacturing processes.

Frequently Asked Questions

What are the main advantages of automated metallurgical testing systems over manual testing?

Automated metallurgical testing systems offer superior accuracy, consistency, and efficiency compared to manual testing methods. They eliminate human error, provide faster results, and can process larger volumes of samples while maintaining detailed documentation of all tests performed. Additionally, these systems can perform complex analyses that would be difficult or impossible to conduct manually.

How do automated testing systems ensure accuracy and reliability?

Automated systems maintain accuracy through precise calibration, standardized procedures, and sophisticated software algorithms. They incorporate multiple quality control checks, continuous monitoring, and self-diagnostic capabilities. Regular system validation and calibration ensure that results remain consistent and reliable over time.

What role will artificial intelligence play in future metallurgical testing?

Artificial intelligence will enhance metallurgical testing by improving pattern recognition, predictive analysis, and decision-making capabilities. AI algorithms will enable more sophisticated defect detection, automated result interpretation, and advanced material behavior prediction. This technology will also facilitate the development of more adaptive and intelligent testing procedures.