Revolutionizing Metal Manufacturing Through Digital Innovation

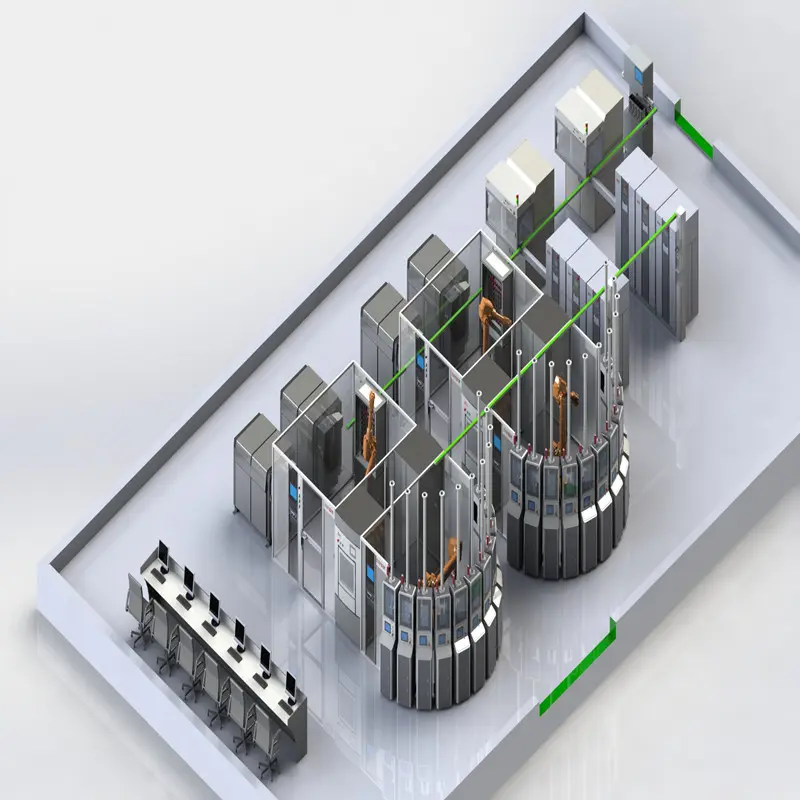

The metallurgical manufacturing industry stands at the cusp of a remarkable transformation, driven by the integration of automated software milling machines. These sophisticated systems are revolutionizing how metal components are designed, produced, and refined, marking a definitive shift from traditional manufacturing methods to smart, software-driven processes. As industries worldwide embrace digital transformation, automated software milling machines have emerged as the cornerstone of modern metalworking, offering unprecedented precision, efficiency, and scalability.

The evolution of these advanced manufacturing systems represents more than just technological progress – it signifies a fundamental change in how manufacturers approach metal fabrication. By combining cutting-edge software controls with precise mechanical engineering, these systems are setting new standards for production quality while simultaneously reducing operational costs and improving workplace safety.

Core Components of Modern Milling Automation

Intelligent Control Systems

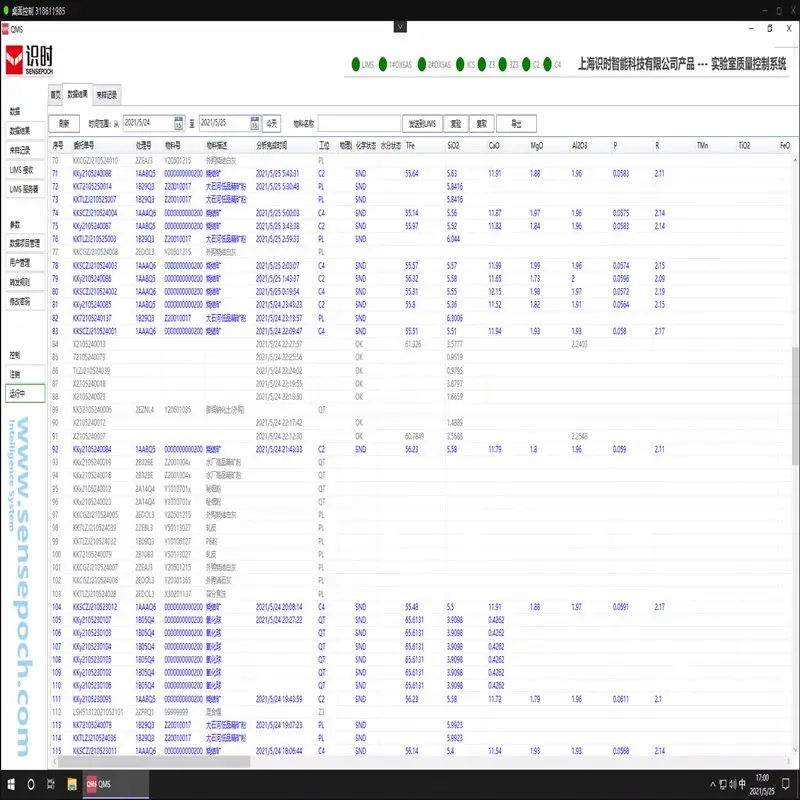

At the heart of automated software milling machines lies sophisticated control systems that coordinate every aspect of the manufacturing process. These systems utilize advanced algorithms to optimize cutting paths, manage tool wear, and adjust operating parameters in real-time. The integration of machine learning capabilities allows these systems to continuously improve their performance, learning from each operation to enhance precision and efficiency.

Modern control interfaces feature intuitive dashboards that provide operators with comprehensive visibility into machine status, production metrics, and maintenance requirements. This level of monitoring ensures optimal performance while minimizing the risk of errors or equipment failure.

Advanced Tooling Technologies

The effectiveness of automated software milling machines heavily depends on their tooling systems. Modern implementations incorporate automatic tool changers, advanced cutting tool materials, and smart tool monitoring systems. These components work in harmony to maintain consistent quality across long production runs while maximizing tool life and minimizing downtime.

Innovative cooling systems and chip management solutions further enhance the capabilities of these machines, allowing for higher cutting speeds and improved surface finishes. The integration of sensor technology enables real-time monitoring of tool wear and cutting conditions, ensuring optimal performance throughout the manufacturing process.

Benefits of Software-Driven Manufacturing

Enhanced Precision and Consistency

The implementation of automated software milling machines brings unprecedented levels of accuracy to metal manufacturing. Computer-controlled operations eliminate human error and maintain consistent quality across production runs, regardless of complexity or volume. The precision achieved by these systems often exceeds traditional manufacturing capabilities, with tolerances measured in microns.

Quality control processes are streamlined through integrated measurement and verification systems, ensuring that each component meets exact specifications. This level of precision not only improves product quality but also reduces waste and rework requirements significantly.

Operational Efficiency and Cost Reduction

The economic advantages of implementing automated software milling machines extend far beyond basic productivity improvements. These systems can operate continuously with minimal supervision, dramatically reducing labor costs while increasing output. The ability to run lights-out operations during off-hours further maximizes equipment utilization and return on investment.

Energy efficiency is another crucial benefit, as modern automated systems optimize power consumption based on actual processing requirements. Combined with reduced material waste and improved tool life, these efficiencies translate into substantial cost savings over traditional manufacturing methods.

Implementation Strategies and Best Practices

Integration Planning

Successfully implementing automated software milling machines requires careful planning and a systematic approach. Organizations must assess their current manufacturing processes, identify integration points, and develop comprehensive implementation strategies. This includes evaluating existing infrastructure, determining training requirements, and establishing clear timelines for deployment.

Change management plays a crucial role in ensuring smooth transition and adoption. Engaging stakeholders early in the process and providing adequate training helps overcome resistance and ensures maximum utilization of new capabilities.

Maintenance and Optimization

Maintaining peak performance of automated software milling machines demands proactive maintenance strategies and continuous optimization efforts. Predictive maintenance programs, supported by real-time monitoring and analytics, help prevent unexpected downtime and extend equipment life. Regular software updates and system optimization ensure that machines continue to operate at maximum efficiency.

Documentation of maintenance procedures and performance metrics enables continuous improvement and helps identify opportunities for further optimization. This data-driven approach to maintenance maximizes equipment reliability and production efficiency.

Future Trends and Developments

Artificial Intelligence Integration

The next evolution in automated software milling machines will be driven by artificial intelligence and advanced analytics. Machine learning algorithms will enable more sophisticated optimization of cutting parameters, predictive maintenance, and adaptive control systems. These developments will further enhance productivity while reducing the need for human intervention in routine operations.

Integration with digital twin technology will allow for more accurate simulation and optimization of manufacturing processes before physical production begins. This capability will significantly reduce setup times and improve first-time-right production rates.

Connected Manufacturing Ecosystems

The future of automated software milling machines lies in their integration with broader manufacturing ecosystems. Industry 4.0 initiatives are driving the development of fully connected manufacturing environments where machines communicate and coordinate activities automatically. This connectivity enables real-time optimization of production schedules, resource allocation, and maintenance activities.

Cloud-based platforms will facilitate remote monitoring and control of manufacturing operations, enabling new levels of flexibility and responsiveness to changing market demands. The ability to analyze production data across multiple machines and facilities will drive continuous improvement in manufacturing efficiency.

Frequently Asked Questions

What are the primary maintenance requirements for automated software milling machines?

Automated software milling machines require regular preventive maintenance, including lubrication system checks, alignment verification, and calibration of control systems. Software updates and backup procedures should be performed according to manufacturer recommendations, while cutting tools need regular inspection and replacement based on wear patterns and usage metrics.

How do automated software milling machines impact workforce requirements?

While these machines reduce the need for manual machine operators, they create demand for skilled technicians and programmers who can manage and optimize the automated systems. Organizations typically need to invest in training existing staff or hiring specialists with expertise in CNC programming, maintenance, and process optimization.

What is the typical return on investment period for automated software milling machines?

The ROI period varies depending on factors such as production volume, complexity of manufactured parts, and current operational costs. However, most organizations report ROI periods of 18-36 months through improved productivity, reduced labor costs, decreased waste, and higher quality output. The ability to operate 24/7 with minimal supervision significantly accelerates the payback period.