In today's competitive business landscape, organizations across industries are increasingly turning to automated systems to streamline operations, reduce costs, and enhance productivity. The strategic implementation of automated solutions has become a critical differentiator for companies seeking to maintain their competitive edge while optimizing resource allocation. These sophisticated systems represent a fundamental shift from traditional manual processes toward intelligent, technology-driven operations that deliver measurable results.

The transformation toward automated operations affects virtually every sector, from manufacturing and healthcare to finance and logistics. Companies that embrace automated technologies consistently report significant improvements in operational efficiency, cost reduction, and overall business performance. Understanding the mechanisms behind these benefits and implementing appropriate automated solutions has become essential for modern business success.

Understanding the Financial Impact of Automation

Direct Cost Reduction Through Process Optimization

Automated systems deliver immediate financial benefits by eliminating redundant processes and reducing the need for manual intervention. When organizations implement automated solutions, they typically experience substantial reductions in labor costs, as fewer personnel are required to manage routine tasks. This cost reduction extends beyond simple workforce considerations to include decreased error rates, reduced waste, and improved resource utilization.

The financial impact becomes particularly evident in high-volume operations where manual processes create bottlenecks. Automated systems process transactions, data entries, and routine calculations at speeds that far exceed human capabilities, resulting in throughput improvements that directly translate to revenue growth. Companies often recover their initial automation investment within months through these operational efficiencies.

Long-term Economic Advantages

Beyond immediate cost savings, automated systems provide long-term economic advantages through scalability and consistency. Unlike human resources, automated systems can handle increased workloads without proportional increases in operational costs. This scalability allows businesses to grow their operations without corresponding increases in overhead expenses, creating sustainable competitive advantages.

The predictability of automated operations also enables better financial planning and resource allocation. Organizations can forecast operational costs more accurately when relying on automated systems, as these technologies provide consistent performance metrics and predictable maintenance requirements. This financial predictability supports strategic decision-making and long-term business planning initiatives.

Time Efficiency Through Automation Technology

Accelerated Processing Capabilities

Modern automated systems excel at processing large volumes of data and transactions in significantly reduced timeframes compared to manual methods. These systems operate continuously without breaks, fatigue, or performance degradation, ensuring consistent productivity levels throughout operational periods. The time savings generated by automated processing allows organizations to reallocate human resources toward higher-value activities that require creativity, strategic thinking, and interpersonal skills.

The speed advantages of automated systems compound over time, creating cumulative time savings that significantly impact overall organizational productivity. Tasks that previously required hours or days to complete manually can often be accomplished in minutes or seconds through automated processes. This acceleration enables businesses to respond more quickly to market changes, customer demands, and operational challenges.

Streamlined Workflow Management

Automated workflow management systems eliminate many of the delays and inefficiencies inherent in manual process coordination. These systems automatically route tasks, documents, and information to appropriate personnel or departments based on predefined rules and criteria. This intelligent routing reduces waiting times, prevents bottlenecks, and ensures that work flows smoothly through organizational processes.

The integration capabilities of automated workflow systems also eliminate time-consuming manual data transfers between different software platforms and departments. Information flows seamlessly through automated channels, reducing the risk of delays caused by human oversight or communication gaps. This integration creates end-to-end process efficiency that maximizes time utilization across entire operational chains.

Quality and Accuracy Improvements

Error Reduction and Consistency

Automated systems significantly reduce human errors that commonly occur in manual processes, particularly in repetitive tasks requiring high attention to detail. These systems follow programmed instructions precisely, ensuring consistent execution without the variability introduced by human factors such as fatigue, distraction, or skill differences. The resulting accuracy improvements reduce costs associated with error correction, rework, and quality control interventions.

The consistency provided by automated systems extends to compliance and regulatory requirements, where precise adherence to established procedures is critical. Automated compliance monitoring and reporting capabilities ensure that organizations maintain required standards without the risk of human oversight or interpretation errors. This consistency protects businesses from regulatory penalties and maintains customer confidence in product and service quality.

Enhanced Data Quality and Reporting

Automated data collection and processing systems provide superior data quality compared to manual methods, capturing information accurately and storing it in standardized formats. This improved data quality enables better decision-making through more reliable analytics and reporting capabilities. Organizations can trust automated data systems to provide accurate, timely information for strategic planning and operational optimization.

Real-time data processing capabilities of automated systems enable immediate visibility into operational performance, allowing management to identify and address issues promptly. This immediate feedback capability prevents small problems from escalating into major operational disruptions, saving both time and money through proactive management approaches.

Strategic Implementation Considerations

Technology Selection and Integration

Successful automation implementation requires careful consideration of technology options and integration requirements within existing organizational infrastructure. Companies must evaluate automated solutions based on their specific operational needs, technical capabilities, and strategic objectives. The selection process should consider factors such as scalability, compatibility, maintenance requirements, and total cost of ownership over the system's expected lifespan.

Integration planning ensures that automated systems work effectively within existing technological ecosystems without disrupting critical business processes. Proper integration strategies minimize implementation risks and maximize the benefits derived from automated investments. Organizations should develop comprehensive integration roadmaps that address technical, operational, and human resource considerations.

Change Management and Training

Effective change management strategies are essential for successful automation adoption, as these implementations often require significant adjustments to established workflows and job responsibilities. Organizations must prepare their workforce for automated system integration through comprehensive training programs and clear communication about the benefits and expectations associated with new technologies.

Employee engagement throughout the automation implementation process helps ensure smooth transitions and maximizes system utilization. When staff members understand how automated systems enhance their work rather than replace it, they become valuable contributors to the implementation success and ongoing optimization efforts.

Industry-Specific Applications

Manufacturing and Production

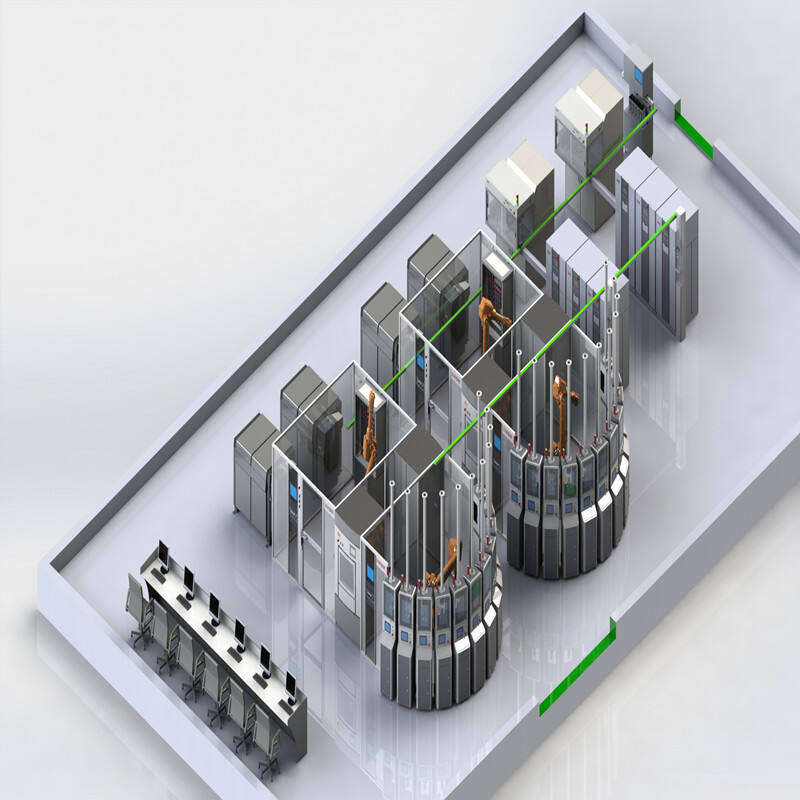

Manufacturing industries have been early adopters of automated systems, implementing robotic assembly lines, quality control systems, and inventory management technologies. These automated solutions have transformed production capabilities, enabling manufacturers to achieve higher output levels while maintaining consistent quality standards. The precision and speed of automated manufacturing systems allow companies to meet demanding production schedules while reducing material waste and labor costs.

Predictive maintenance systems represent another significant application of automation in manufacturing, using sensor data and analytics to anticipate equipment failures before they occur. This proactive approach prevents costly production downtime and extends equipment lifespan, contributing to substantial cost savings and improved operational reliability.

Financial Services and Banking

Financial institutions leverage automated systems for transaction processing, fraud detection, compliance monitoring, and customer service functions. These applications handle millions of transactions daily with accuracy levels that would be impossible to achieve through manual processes. Automated financial systems also provide enhanced security features that protect sensitive customer information and prevent unauthorized access.

Risk assessment and credit evaluation processes benefit significantly from automated analysis capabilities that can process complex financial data and market conditions in real-time. These systems enable faster decision-making while maintaining rigorous analysis standards, improving customer satisfaction and competitive positioning in dynamic financial markets.

Measuring Return on Investment

Quantitative Performance Metrics

Organizations implementing automated systems must establish clear metrics for measuring return on investment and operational improvements. Key performance indicators typically include processing speed improvements, error rate reductions, cost per transaction decreases, and productivity gains measured against baseline manual processes. These quantitative metrics provide objective evidence of automation benefits and support continued investment decisions.

Comprehensive ROI analysis should consider both direct and indirect benefits of automated systems implementation. While direct benefits include obvious cost and time savings, indirect benefits encompass improved customer satisfaction, enhanced competitive positioning, and increased organizational agility. Tracking these comprehensive benefits provides a complete picture of automation value.

Continuous Optimization Strategies

Successful automation implementations require ongoing optimization efforts to maximize system performance and adapt to changing business requirements. Regular performance reviews and system updates ensure that automated solutions continue to deliver optimal results as organizational needs evolve. This continuous improvement approach maximizes the long-term value of automation investments.

Advanced analytics capabilities enable organizations to identify optimization opportunities within their automated systems, fine-tuning performance parameters to achieve even greater efficiency gains. These data-driven optimization strategies help organizations stay ahead of competitive pressures while maintaining operational excellence.

FAQ

What types of businesses benefit most from automated systems

Businesses with high-volume, repetitive processes typically see the greatest benefits from automated systems implementation. This includes manufacturing companies, financial institutions, healthcare organizations, logistics providers, and retail operations. However, virtually any business can benefit from automation in areas such as customer service, data processing, inventory management, or compliance monitoring. The key is identifying processes that are time-consuming, error-prone, or resource-intensive when performed manually.

How long does it typically take to see ROI from automation investments

Return on investment timelines vary depending on the complexity and scope of automated system implementation, but most organizations begin seeing measurable benefits within 3-12 months. Simple process automation may deliver ROI within weeks, while comprehensive enterprise automation systems might require 12-24 months to fully realize their potential. Factors affecting ROI timeline include implementation complexity, staff training requirements, integration challenges, and the scale of processes being automated.

What are the main challenges in implementing automated systems

Common implementation challenges include integration with existing systems, staff resistance to change, initial investment costs, and technical complexity. Organizations often underestimate the importance of change management and employee training in successful automation adoption. Technical challenges may include data migration, system compatibility issues, and ensuring adequate security measures. Proper planning, stakeholder engagement, and phased implementation strategies help address these challenges effectively.

How do automated systems handle unexpected situations or exceptions

Modern automated systems incorporate exception handling capabilities that can manage unexpected situations through predefined rules and escalation procedures. When systems encounter situations outside their programmed parameters, they typically flag these exceptions for human review while continuing to process routine tasks. Advanced systems use machine learning algorithms to adapt to new situations and improve their exception handling capabilities over time. Organizations should establish clear procedures for handling exceptions and regularly review system performance to identify areas for improvement.