системы пневматических трубчатых контейнеров

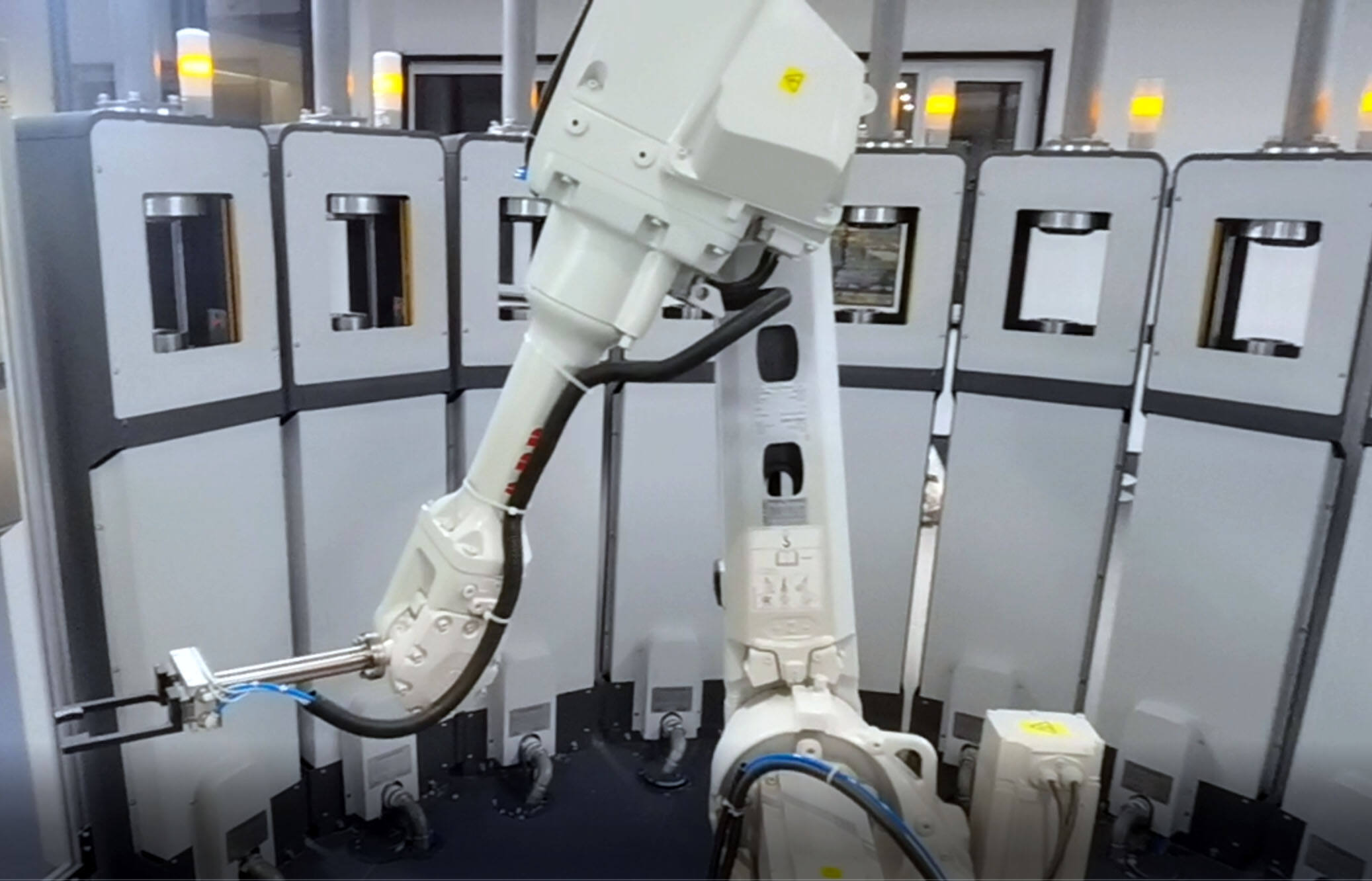

Системы пневматических транспортных капсул представляют революционный подход к логистике внутренних перевозок, используя сжатый воздух для перемещения капсул по сети трубопроводов. Эти системы состоят из взаимосвязанных труб, автоматизированных станций отправки и приема, а также сложного программного обеспечения управления, которое контролирует всю операцию. Специально разработанные цилиндрические капсулы могут перевозить различные предметы, включая документы, медицинские препараты, лабораторные образцы и небольшие грузы весом до нескольких килограммов. Работа системы основана на создании перепадов давления внутри трубопроводной сети, которые либо толкают, либо тянут капсулы к назначенным пунктам назначения со скоростью, как правило, от 3 до 25 метров в секунду. Современные пневматические транспортные системы оснащены передовыми функциями, такими как радиочастотная идентификация (RFID), алгоритмы автоматической маршрутизации и возможность мониторинга в режиме реального времени. Их можно устанавливать в различных конфигурациях — от простых соединений «точка-точка» до сложных сетей с несколькими станциями и возможностями маршрутизации. Технология значительно эволюционировала со времен своего возникновения, теперь в нее входят сенсорные интерфейсы, опции приоритетной маршрутизации и комплексная диагностика систем. Такие системы широко используются в медицинских учреждениях, лабораториях, торговых предприятиях и промышленных условиях, где особенно важна быстрая и безопасная доставка материалов.