Revolutionizing Material Testing Through Advanced Automation

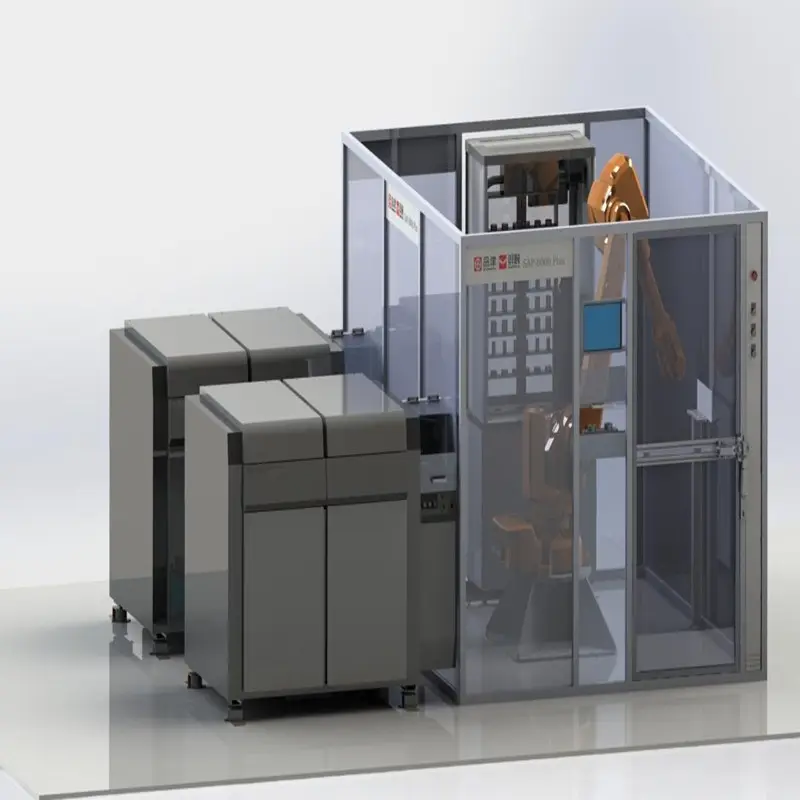

The landscape of materials science and engineering has undergone a remarkable transformation with the emergence of automated instrument systems for metallurgical analysis. These sophisticated tools have redefined how we understand, test, and validate metal properties, ushering in an era of unprecedented precision and efficiency in materials characterization. From quality control in manufacturing to breakthrough research in materials development, automated systems have become the cornerstone of modern metallurgical investigation.

As industries push the boundaries of material capabilities, the demand for more accurate, repeatable, and comprehensive metallurgical analysis continues to grow. Automated instrument systems address these needs by combining cutting-edge sensor technology, advanced data processing, and intelligent automation to deliver results that surpass traditional testing methods in both speed and reliability.

Core Components of Modern Metallurgical Analysis Systems

Advanced Sensing Technologies

At the heart of automated metallurgical analysis systems lies an array of sophisticated sensors that capture detailed information about material properties. These include high-resolution optical sensors for surface analysis, spectroscopic devices for chemical composition determination, and advanced probes for mechanical property assessment. The integration of multiple sensing technologies enables a comprehensive evaluation of material characteristics in a single automated workflow.

Modern sensors employ various physical principles, from X-ray fluorescence to electron microscopy, ensuring that every aspect of the material's structure and composition can be accurately measured. This multi-modal approach to metallurgical analysis provides a more complete understanding of material properties than ever before possible.

Data Processing and Analysis Software

The true power of automated metallurgical analysis systems emerges through their sophisticated data processing capabilities. Advanced algorithms process raw sensor data in real-time, applying complex analytical models to extract meaningful insights about material properties. Machine learning algorithms help identify patterns and anomalies that might be missed by conventional analysis methods.

These software systems not only handle data processing but also provide intuitive visualization tools that help metallurgists and engineers interpret results effectively. The ability to generate detailed reports automatically saves valuable time while ensuring consistency in documentation.

Benefits of Automation in Metallurgical Testing

Enhanced Precision and Repeatability

Automated systems have dramatically improved the precision of metallurgical analysis by eliminating human variability from the testing process. Through standardized procedures and calibrated instruments, these systems ensure consistent results across multiple tests and different operators. This level of repeatability is crucial for quality control and research applications where reliable data is essential.

The improved accuracy extends beyond basic measurements to complex analysis procedures, where automated systems can maintain precise control over test conditions and parameters. This consistency leads to more reliable material characterization and better-informed decision-making in product development and manufacturing.

Increased Throughput and Efficiency

The implementation of automated metallurgical analysis systems has revolutionized laboratory productivity. What once took hours or days of manual testing can now be accomplished in minutes or hours, with minimal human intervention. This increased efficiency allows laboratories to handle larger sample volumes and respond more quickly to urgent analysis requests.

Beyond speed, automation reduces operating costs by minimizing the need for specialized training and reducing the risk of operator error. The systems can run continuously, maximizing equipment utilization and return on investment.

Applications Across Industries

Manufacturing Quality Control

In manufacturing environments, automated metallurgical analysis systems serve as crucial quality control tools. They enable real-time monitoring of production processes, helping identify potential issues before they become costly problems. The ability to quickly analyze material properties ensures that products meet specifications and regulatory requirements.

These systems are particularly valuable in industries with strict quality standards, such as aerospace and automotive manufacturing, where material failures can have severe consequences. Automated analysis helps maintain consistent product quality while documenting compliance with industry standards.

Research and Development

For research institutions and development laboratories, automated metallurgical analysis systems accelerate the pace of innovation. They enable rapid testing of new materials and alloys, providing detailed data that helps researchers understand structure-property relationships and optimize material compositions.

The high-throughput capabilities of these systems allow researchers to explore more material combinations and processing conditions than would be possible with manual testing methods. This accelerates the development of new materials and improves our understanding of existing ones.

Future Trends in Automated Metallurgical Analysis

Integration with Industry 4.0

The future of metallurgical analysis lies in deeper integration with Industry 4.0 principles. Smart factories will increasingly rely on automated analysis systems that communicate with other production equipment, creating a seamless flow of data and enabling predictive quality control. This connectivity will allow for real-time adjustments to manufacturing processes based on material analysis results.

Cloud computing and edge processing will play larger roles in handling the massive amounts of data generated by these systems, enabling more sophisticated analysis and better prediction of material behavior.

Artificial Intelligence and Machine Learning Applications

The integration of AI and machine learning into metallurgical analysis systems represents the next frontier in materials characterization. These technologies will enable more sophisticated pattern recognition, automated defect classification, and predictive maintenance capabilities. Advanced algorithms will help identify subtle correlations in material properties that might otherwise go unnoticed.

As these systems become more intelligent, they will increasingly assist in material design and optimization, suggesting modifications to improve performance based on analysis results.

Frequently Asked Questions

What advantages do automated metallurgical analysis systems offer over manual testing?

Automated systems provide higher accuracy, better repeatability, and significantly faster testing speeds compared to manual methods. They eliminate human error, reduce operating costs, and enable continuous operation while maintaining consistent quality standards in analysis.

How do automated systems ensure accuracy in metallurgical analysis?

These systems employ precise calibration procedures, multiple validation steps, and sophisticated error-checking algorithms. They also utilize standardized testing protocols and maintain stable testing conditions throughout the analysis process, ensuring reliable and accurate results.

What training is required to operate automated metallurgical analysis systems?

While automated systems significantly reduce the need for specialized training, operators still require basic understanding of metallurgical principles and system operation. Most manufacturers provide comprehensive training programs that cover system operation, maintenance, and data interpretation.

How often should automated metallurgical analysis systems be calibrated?

Calibration frequency depends on usage patterns and manufacturer recommendations, but most systems require regular calibration checks daily or weekly. Many modern systems include automated calibration features and monitoring tools to ensure continued accuracy.

Table of Contents

- Revolutionizing Material Testing Through Advanced Automation

- Core Components of Modern Metallurgical Analysis Systems

- Benefits of Automation in Metallurgical Testing

- Applications Across Industries

- Future Trends in Automated Metallurgical Analysis

-

Frequently Asked Questions

- What advantages do automated metallurgical analysis systems offer over manual testing?

- How do automated systems ensure accuracy in metallurgical analysis?

- What training is required to operate automated metallurgical analysis systems?

- How often should automated metallurgical analysis systems be calibrated?