In today's rapidly evolving industrial landscape, organizations face a critical decision that can significantly impact their operational efficiency, cost-effectiveness, and competitive advantage. The choice between automated systems and manual processes has become more complex as technology advances and business requirements become increasingly sophisticated. While traditional manual methods have served industries well for decades, the emergence of sophisticated automated solutions is reshaping how companies approach their core operations. Understanding the fundamental differences, advantages, and limitations of each approach is essential for making informed decisions that align with organizational goals and long-term strategic objectives.

Understanding Automated Systems

Core Components of Automation Technology

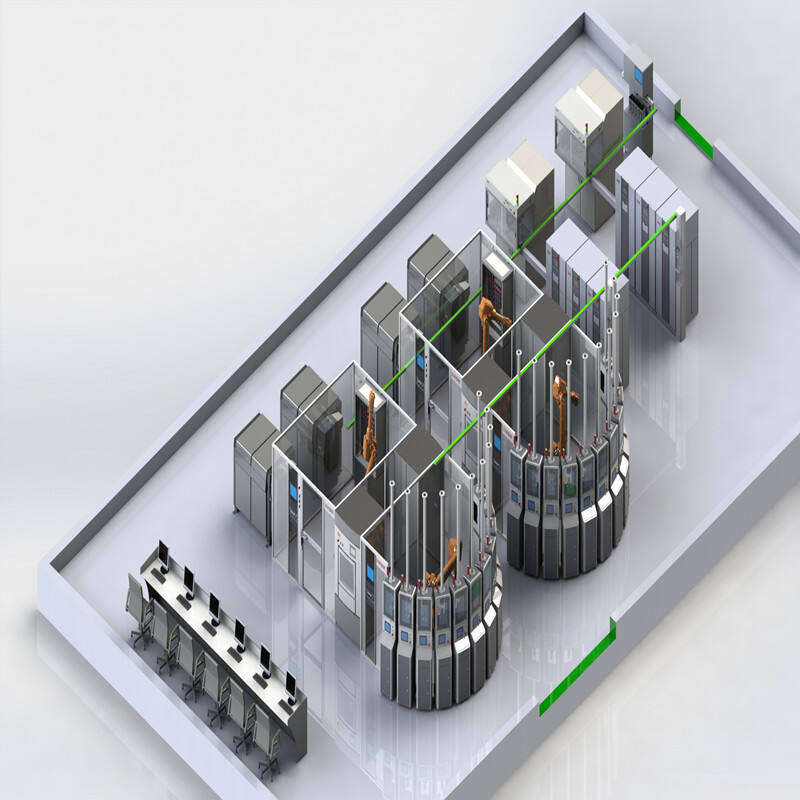

Modern automated systems represent a convergence of multiple technological disciplines, combining advanced sensors, artificial intelligence, machine learning algorithms, and sophisticated control mechanisms. These systems are designed to execute predetermined tasks with minimal human intervention, utilizing feedback loops and real-time data processing to maintain optimal performance levels. The integration of Internet of Things devices, cloud computing platforms, and edge computing capabilities has expanded the scope and effectiveness of automated solutions across various industrial sectors. Contemporary automated systems can adapt to changing conditions, learn from operational patterns, and continuously optimize their performance through sophisticated algorithms and predictive analytics.

The technological foundation of automated systems relies heavily on standardized communication protocols, robust cybersecurity measures, and scalable architecture that can accommodate future expansion and technological upgrades. These systems incorporate redundancy mechanisms, fail-safe protocols, and comprehensive monitoring capabilities to ensure consistent operation and minimize the risk of unexpected failures. Advanced automated solutions also feature intuitive user interfaces, comprehensive reporting capabilities, and integration points that allow seamless connectivity with existing enterprise systems and third-party applications.

Implementation Strategies and Considerations

Successful implementation of automated systems requires careful planning, comprehensive stakeholder engagement, and a thorough understanding of existing operational workflows and requirements. Organizations must evaluate their current infrastructure, identify potential integration challenges, and develop phased implementation strategies that minimize operational disruption while maximizing the benefits of automation technology. The implementation process typically involves detailed requirement analysis, system design, configuration, testing, training, and ongoing support activities that ensure optimal system performance and user adoption.

Change management becomes a critical factor in automated system implementation, as organizations must address employee concerns, provide adequate training, and establish new operational procedures that leverage the capabilities of automated solutions. The transition period often requires parallel operation of manual and automated processes, allowing organizations to validate system performance, identify optimization opportunities, and gradually shift operational responsibilities to automated systems while maintaining operational continuity and quality standards.

Manual Process Advantages and Applications

Human Expertise and Decision-Making Capabilities

Manual processes leverage the unique capabilities of human operators, including complex problem-solving skills, intuitive decision-making abilities, and the capacity to handle unexpected situations that may not be adequately addressed by predetermined automated protocols. Human operators possess the ability to recognize subtle patterns, make contextual judgments, and adapt their approach based on experience and situational awareness that extends beyond programmed parameters. This flexibility becomes particularly valuable in environments where variability is high, where creative solutions are required, or where the consequences of incorrect decisions have significant implications.

The human element in manual processes provides valuable oversight, quality control, and the ability to intervene when circumstances deviate from normal operating parameters. Experienced operators can identify potential issues before they become critical problems, apply their knowledge and expertise to optimize processes in real-time, and make nuanced decisions that consider multiple factors simultaneously. Manual processes also facilitate direct communication, collaborative problem-solving, and the transfer of tacit knowledge that contributes to organizational learning and continuous improvement initiatives.

Cost Considerations and Resource Requirements

Manual processes often require lower initial capital investment compared to sophisticated automated systems, making them attractive options for organizations with limited budgets or those operating in markets with uncertain demand patterns. The implementation of manual processes typically involves lower upfront costs for equipment, software, and system integration, although ongoing operational costs may be higher due to labor requirements, training needs, and potential variability in performance outcomes. Organizations can implement manual processes more quickly, with shorter lead times and reduced complexity in terms of system design, configuration, and validation.

However, manual processes may involve higher long-term operational costs due to labor expenses, training requirements, potential for human error, and limitations in terms of scalability and consistency. Organizations must carefully evaluate the total cost of ownership, considering factors such as labor costs, training expenses, error rates, productivity levels, and the potential for process improvement over time when comparing manual approaches with automated alternatives.

Comparative Analysis of Efficiency and Performance

Speed and Throughput Considerations

Automated systems typically demonstrate superior performance in terms of processing speed, throughput capacity, and consistency of output when compared to manual processes. These systems can operate continuously without fatigue, maintain consistent performance levels regardless of external factors, and process large volumes of work with minimal variation in quality or timing. The ability of automated systems to work around the clock, maintain precise timing, and execute complex sequences of operations with high accuracy makes them particularly suitable for high-volume, repetitive tasks that require consistent quality standards.

Manual processes, while potentially slower in terms of raw throughput, offer advantages in terms of flexibility, adaptability, and the ability to handle complex or non-standard situations that may challenge automated systems. Human operators can adjust their approach in real-time, handle variations in input materials or conditions, and make quality assessments that consider factors beyond predetermined specifications. The trade-off between speed and flexibility becomes a critical consideration when evaluating the most appropriate approach for specific applications and operational requirements.

Quality Control and Error Management

Quality control represents another important dimension in the comparison between automated and manual processes, with each approach offering distinct advantages and challenges. Automated systems provide consistent execution of predefined quality control protocols, comprehensive data logging, and the ability to detect and respond to variations that fall outside acceptable parameters. These systems can implement sophisticated statistical process control methods, maintain detailed quality records, and provide real-time feedback on process performance and quality metrics.

Manual processes rely on human judgment, experience, and sensory capabilities to assess quality, identify potential issues, and make corrective adjustments. While human operators may be more susceptible to fatigue, distraction, or inconsistency, they also possess the ability to recognize subtle quality indicators, make contextual assessments, and identify problems that may not be detected by automated systems. The integration of human oversight with automated quality control systems often provides the most comprehensive approach to quality management, combining the consistency of automated monitoring with the judgment and adaptability of human expertise.

Cost-Benefit Analysis Framework

Initial Investment and Implementation Costs

The financial analysis of automated versus manual processes must consider both immediate implementation costs and long-term operational implications to provide a comprehensive understanding of the economic impact of each approach. Automated systems typically require significant upfront investment in hardware, software, system integration, training, and validation activities, but may offer lower ongoing operational costs through reduced labor requirements, improved efficiency, and enhanced consistency. The initial investment in automated systems can be substantial, particularly for complex applications that require custom development, extensive integration, or specialized equipment.

Manual processes generally involve lower initial costs but may require ongoing investments in training, supervision, quality control, and process improvement initiatives. The cost structure of manual processes is often more predictable in the short term but may become less favorable over time as labor costs increase, training requirements evolve, and competitive pressures demand higher levels of efficiency and consistency. Organizations must evaluate the payback period, return on investment, and long-term cost trends when making decisions about process automation.

Long-term Operational Economics

Long-term operational economics involve complex considerations including maintenance costs, technology obsolescence, scalability requirements, and changing market conditions that may affect the relative attractiveness of automated versus manual approaches. Automated systems may require ongoing maintenance, software updates, technical support, and periodic upgrades to maintain optimal performance and compatibility with evolving technology standards. However, these systems often provide predictable cost structures, improved resource utilization, and the potential for continuous optimization through data analysis and process refinement.

Manual processes may offer greater flexibility in terms of cost management, allowing organizations to adjust labor levels based on demand fluctuations, seasonal variations, or changing business requirements. However, manual processes may face challenges related to labor availability, skill requirements, wage inflation, and the need for ongoing training and development to maintain competency levels. The economic analysis must also consider intangible factors such as employee satisfaction, organizational capability development, and strategic positioning in competitive markets.

Industry-Specific Applications and Recommendations

Manufacturing and Production Environments

Manufacturing environments present diverse opportunities for both automated and manual processes, with the optimal choice depending on factors such as production volume, product complexity, quality requirements, and market dynamics. High-volume, standardized production typically benefits from automated systems that can maintain consistent quality, operate continuously, and achieve economies of scale through efficient resource utilization. Automated manufacturing systems excel in applications requiring precise timing, consistent quality, and integration with supply chain management systems and quality control protocols.

Conversely, custom manufacturing, prototype development, and low-volume production may be better served by manual processes that offer flexibility, adaptability, and the ability to accommodate frequent design changes or special requirements. Manual processes in manufacturing environments provide advantages when dealing with complex assemblies, specialized materials, or applications requiring human judgment and problem-solving capabilities that extend beyond programmed parameters.

Service Industries and Knowledge Work

Service industries and knowledge-based work present unique considerations for the automation versus manual process decision, as these environments often involve complex interpersonal interactions, creative problem-solving, and contextual decision-making that may be challenging to automate effectively. Automated systems in service environments can handle routine transactions, data processing, scheduling, and customer service inquiries that follow standard protocols, freeing human resources for more complex and value-added activities.

Manual processes remain essential in service industries for activities requiring empathy, creative problem-solving, relationship building, and complex decision-making that considers multiple stakeholders and contextual factors. The integration of automated tools to support manual processes often provides the optimal approach, combining the efficiency of automation with the human capabilities required for effective service delivery and customer relationship management.

Future Trends and Technological Evolution

Emerging Technologies and Capabilities

The landscape of automation technology continues to evolve rapidly, with emerging technologies such as artificial intelligence, machine learning, advanced robotics, and cognitive computing expanding the scope and capabilities of automated systems. These technologies are enabling automated systems to handle increasingly complex tasks, adapt to changing conditions, and make sophisticated decisions that were previously the exclusive domain of human operators. The integration of natural language processing, computer vision, and predictive analytics is creating opportunities for automated systems to interact more effectively with human operators and handle unstructured data and complex scenarios.

Future developments in automation technology are likely to focus on improving system flexibility, reducing implementation complexity, and enhancing the integration between automated systems and human operators. Collaborative robotics, augmented reality interfaces, and intuitive programming tools are making automated systems more accessible and easier to implement across diverse applications and organizational contexts. These technological advances are reducing the barriers to automation adoption while expanding the range of applications where automated solutions can provide significant value.

Integration and Hybrid Approaches

The future of process optimization increasingly points toward hybrid approaches that combine the strengths of both automated and manual processes, creating integrated solutions that leverage the unique capabilities of each approach. These hybrid systems allow organizations to automate routine, high-volume tasks while maintaining human oversight and intervention capabilities for complex decision-making, exception handling, and continuous improvement activities. The development of sophisticated human-machine interfaces and collaborative technologies is facilitating seamless integration between automated systems and human operators.

Hybrid approaches enable organizations to achieve optimal performance by utilizing automated systems for tasks requiring speed, consistency, and precision while employing human capabilities for activities requiring creativity, judgment, and adaptability. This integrated approach often provides superior results compared to purely automated or manual processes, allowing organizations to optimize their operations while maintaining flexibility and responsiveness to changing requirements and market conditions.

FAQ

What factors should organizations consider when choosing between automated and manual processes

Organizations should evaluate multiple factors including initial investment costs, long-term operational expenses, required throughput levels, quality standards, flexibility needs, available expertise, and strategic objectives. The decision should also consider industry-specific requirements, regulatory compliance needs, scalability expectations, and the potential for future technology evolution. A comprehensive analysis should include total cost of ownership calculations, risk assessments, and alignment with organizational capabilities and strategic goals.

How can companies minimize risks when implementing automated systems

Risk mitigation strategies for automation implementation include conducting thorough requirement analysis, developing phased implementation plans, maintaining parallel manual processes during transition periods, investing in comprehensive training programs, establishing robust backup and recovery procedures, and implementing continuous monitoring and maintenance protocols. Organizations should also ensure adequate cybersecurity measures, establish clear governance structures, and maintain access to technical support and expertise throughout the implementation and operational phases.

Can manual and automated processes coexist effectively in the same organization

Yes, many successful organizations implement hybrid approaches that combine automated and manual processes to optimize overall performance and flexibility. This coexistence requires careful planning, clear process definitions, effective communication protocols, and integrated management systems that coordinate between different operational approaches. The key is identifying the optimal application for each approach based on specific requirements, constraints, and organizational capabilities while ensuring seamless integration and consistent quality standards across all processes.

What are the most important performance metrics for comparing automated and manual processes

Critical performance metrics include throughput rates, quality indicators, error rates, cost per unit, resource utilization, cycle times, customer satisfaction scores, and return on investment calculations. Organizations should also monitor flexibility measures, scalability indicators, maintenance requirements, training costs, and strategic alignment metrics. The selection of appropriate metrics should reflect organizational priorities, industry standards, and specific operational objectives while providing actionable insights for continuous improvement and decision-making purposes.

Table of Contents

- Understanding Automated Systems

- Manual Process Advantages and Applications

- Comparative Analysis of Efficiency and Performance

- Cost-Benefit Analysis Framework

- Industry-Specific Applications and Recommendations

- Future Trends and Technological Evolution

-

FAQ

- What factors should organizations consider when choosing between automated and manual processes

- How can companies minimize risks when implementing automated systems

- Can manual and automated processes coexist effectively in the same organization

- What are the most important performance metrics for comparing automated and manual processes